Commercial Beer Filtration Systems from a Professional Manufacturer

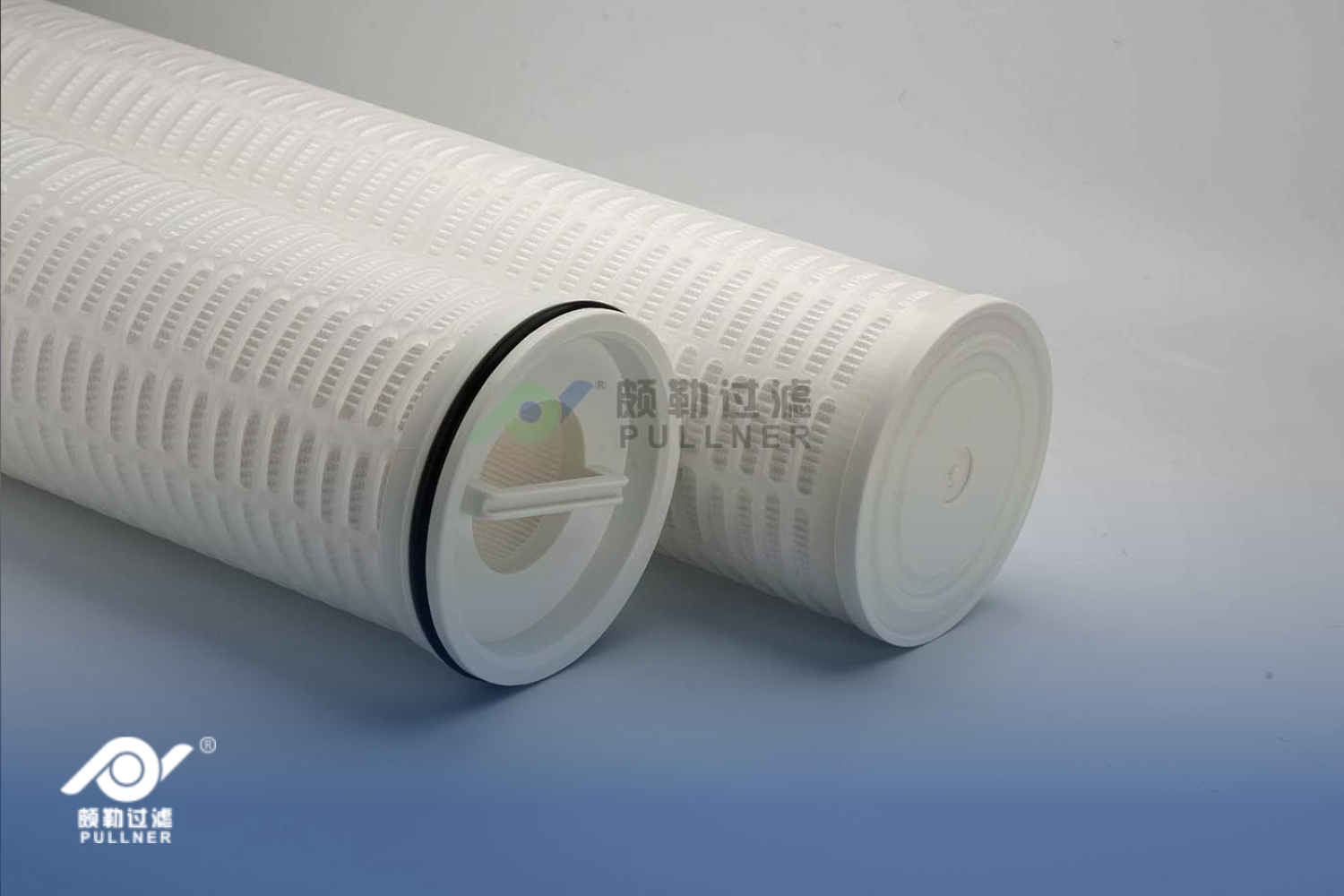

Pullner designs and manufactures advanced commercial beer filtration systems for breweries seeking clarity, flavor consistency and microbiological stability.

Our beer brewing filters and custom-built filtration systems are engineered for commercial breweries, craft operations and contract brewing setups of every scale.

- High-flow beer filtration equipment for all stages of brewing, from fermentation to final polish

- Custom beer brewing filter cartridges to remove yeast, haze and sediment

- Hygienic filter housings and membranes designed to protect beer quality and shelf life

Beer Filtration Systems for Brewing Applications

From small-batch craft producers to high-volume breweries, our commercial beer filtration systems help you maintain consistent flavor, clarity and stability throughout the brewing process.

Whether you’re managing fermentation, haze control or final polishing, our beer filtration equipment supports each stage with precision-engineered filter systems.

Our brewery filtration systems are trusted worldwide for their hygienic design, easy integration and performance in demanding production environments.

Our Commercial Beer Filtration System Capabilities

We design and manufacture every part of the commercial beer filtration system, including food-grade filter housings, end caps and filter cartridges.

Our systems are compatible with stainless steel, pleated media, PES and PTFE membranes, ensuring reliability across brewery setups.

All beer brewing filters are produced in ISO-class cleanrooms, maintaining strict cleanliness standards for brewing operations.

Each beer filtration system is tested for microbial retention, particle capture and contaminant control to support long-term beer quality.

We offer pore-size control down to 0.45 μm, ideal for removing yeast and spoilage organisms during final polishing.

Flow rate and pressure-drop testing ensure that every beer brewing filter supports consistent throughput without altering flavor or clarity.

Pullner offers a full range of brewing filters including trap, pre-filter, membrane and polishing types.

Our filters are available in plate-and-frame, lenticular, depth and capsule formats to fit any brewery filtration system.

Our filtration systems are fully compatible with clean-in-place (CIP) and sterilize-in-place (SIP) procedures.

We engineer long-life filters to endure repeated sanitization cycles without compromising integrity or filtration performance.

From installation support to scheduled replacements, our international service teams help commercial and craft breweries keep filtration running smoothly.

We supply complete system guidance, filter selection advice and rapid logistics support.

Why Choose Pullner for Your Commercial Beer Filtration System?

Trusted Commercial Beer Filtration Systems

Pullner’s commercial beer filtration systems are used by commercial breweries and craft brewers worldwide to maintain clarity, shelf life and high-quality production.

Custom Filters for Every Brewing Step

We offer tailored beer brewing filters and beer brewing filter cartridges matched to your specific brew style, micron rating and system layout.

Advanced Membrane Technology

Our high-efficiency membranes provide microbial control without stripping aroma or taste. Available in 0.45 to 5 μm ratings, these filters are ideal for yeast and haze removal during trap and polishing stages.

Built for Repeat Use and Easy Integration

Each filter system is CIP/SIP-compatible and built to integrate into standard skid-mounted or modular brewery setups. We use durable materials and food-safe filter housings.

Worldwide Support and Fast Delivery

With fast lead times and support across brewing regions, Pullner ensures you get the filter, equipment and support you need to keep production flowing, whether you’re scaling up or running pilot batches.

Our Beer Filtration Systems In Action

Wort Clarification

Pullner’s commercial beer filtration systems help brewers remove hot trub, hop residue and solids from wort before fermentation begins.

This early-stage filtration reduces impurities, protects downstream equipment, and improves the consistency of your final beer.

Trap Filtration (Post-Fermentation)

After fermentation, yeast cells, proteins, and haze-forming particles remain suspended.

Our beer brewing filters provide effective trap filtration to remove these solids without stripping flavor or aroma, supporting clarity and microbial stability.

Pre-Carbonation Filtration

Our beer filtration equipment includes pre-carbonation filters designed to capture remaining particles before the beer reaches carbonation tanks.

This stage prevents fouling and ensures the finished filtered beer remains clean and shelf-stable.

Final Polishing

Polishing filters, typically 0.45 μm-rated membranes, provide the final layer of protection.

These beer brewing filters remove fine haze, residual yeast and spoilage organisms while preserving mouthfeel, color, and the taste of the beer, which is key for maintaining premium beer quality.

Craft Brewing & Scalability

Whether running a microbrewery or expanding craft operation, Pullner offers brewery filtration systems with modular formats, from capsule units to full skid-mounted filtration systems. Every filter is engineered for performance, hygiene and repeatable results.

Features of Our Beer Filtration Systems

Wide Range of Micron Ratings

We offer filters from 0.45 μm to 5 μm to support yeast reduction, trap filtration and final polishing.

Selecting the right micron rating is highly important for controlling haze, flavor stability and shelf life without over-filtering your beer.

Low Pressure Drop, High Flow Performance

Our commercial beer filtration systems are engineered for high-volume throughput while maintaining low pressure drop.

This ensures gentle product handling, reliable carbonation and consistent flow during continuous brewery production.

Fully Traceable Manufacturing

All filters are batch-tested and fully traceable, helping you meet brewery audit and quality control requirements.

We provide documentation for every beer filtration system, including test data, compliance specs and replacement guidance.

Our Commercial Beer Filtration Equipment

Commercial Beer Filtration System FAQs

Yes, our commercial beer filtration systems are modular and scalable, making them suitable for both small craft brewers and high-volume commercial breweries. We offer everything from capsule units to full CIP-compatible skids.

For final polishing, a micron rating of 0.45 μm is typically ideal to remove particles and spoilage organisms without stripping flavor. Coarser filters (5 μm) may be used earlier in the process for impurity reduction or trap filtration.

Yes, our filter cartridges and filter housings are designed to fit industry-standard dimensions and configurations. Whether you’re retrofitting a plate-and-frame setup or upgrading a modular filtration system, we can supply matched components.

Changeout frequency depends on your beer, filter type and throughput. Pullner helps you set optimal service intervals to protect beer quality while minimizing waste and downtime.

Your Commercial Beer Filtration System is Just a Few Clicks Away

Our commercial beer filtration systems are trusted by breweries worldwide to improve clarity, stability, and beer quality at every stage of production. Let our team help you choose the right beer filtration system and optimize your process with durable, hygienic and high-performance filter solutions.