Commercial Water Filtration Systems to Keep Business Running Smoothly

Commercial sites can’t run on inconsistent water. Our commercial water filtration system lineup gives you staged water treatment that protects equipment, stabilizes quality and supports compliance across process, potable, cooling and reuse applications.

Pullner Filter designs and manufactures each system in-house, sizes it to your water profile and flow demand and supports you through commissioning and long-term spares.

- ISO 9001 certification

- 4,000 filters/day turnaround

- Global support teams

Commercial Water Filtration Systems We Offer

What a Commercial Water Filtration System Does

A commercial water filtration system removes sediment, heavy metals and contaminants that lead to scaling, corrosion, fouling and microbial risk in high-use facilities. You get high-quality water that keeps equipment operating efficiently and protects process outcomes.

Most sites need a staged approach. Start with coarse removal to stabilize flow, follow with primary filtration to carry the solids load, then add specialty treatment only where your process specs or regulations call for it. For drinking water applications, prioritize sediment control, chlorine reduction and microbial safety.

Benefits for Commercial And Industrial Sites

The right filtration system pays for itself in uptime, maintenance savings and compliance confidence. Benefits vary depending on the commercial business.

Filtration prevents scale, debris and hard water from damaging boilers, chillers, cooling towers and heat exchangers, extending service life and reducing emergency repairs.

Stable water reduces variation in washing, mixing, cooling and coating steps, helping you protect batch quality and lower rejects.

Cleaner feedwater lowers dosing requirements and improves heat transfer, which reduces energy draw in heating and cooling systems.

Well-sized pretreatment and predictable consumables prevent pressure drops, unexpected clogging and unplanned shutdowns.

Filtration helps you meet potable, process or discharge standards and unlocks water recovery for reuse where regulations allow.

How a Commercial Water Filtration System Works

Commercial and industrial water filtration relies on staged removal. Each stage targets a specific contaminant group so you reach your water purification target without overspending.

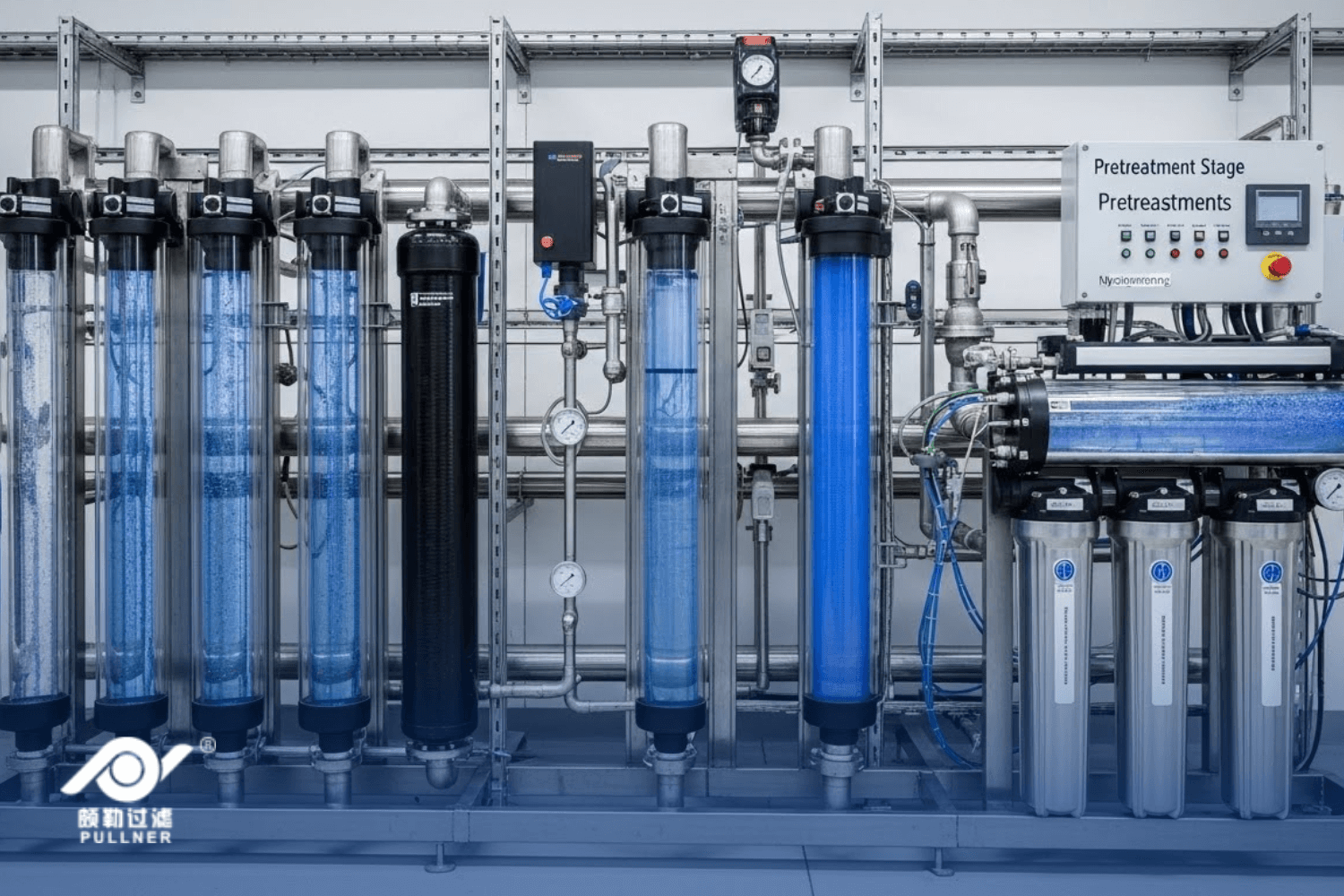

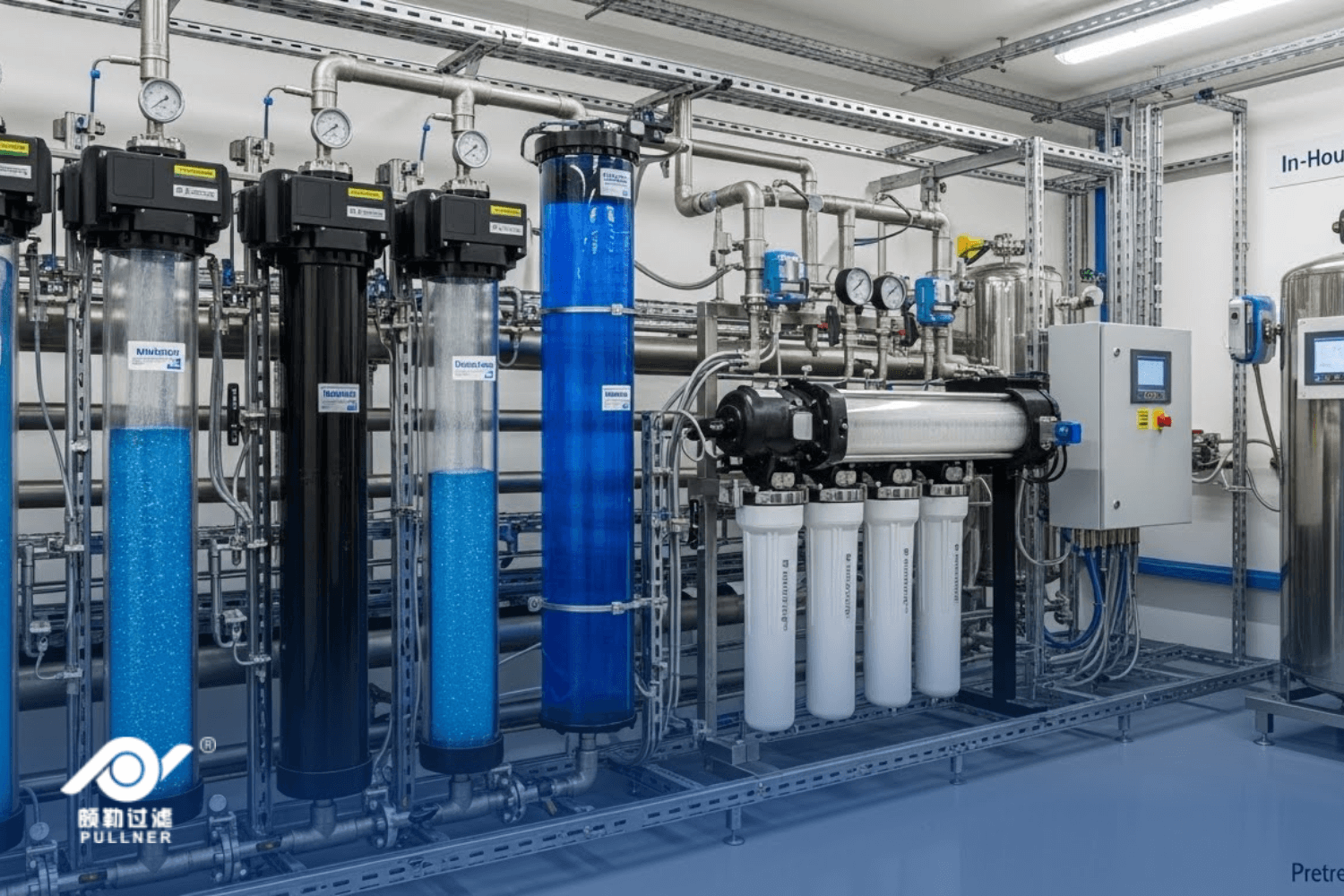

1. Pretreatment Stage

Pretreatment removes coarse sediment and stabilizes your flow. Media filtration, strainers or bag systems reduce load on fine filters and improve system longevity.

2. Primary Filtration Stage

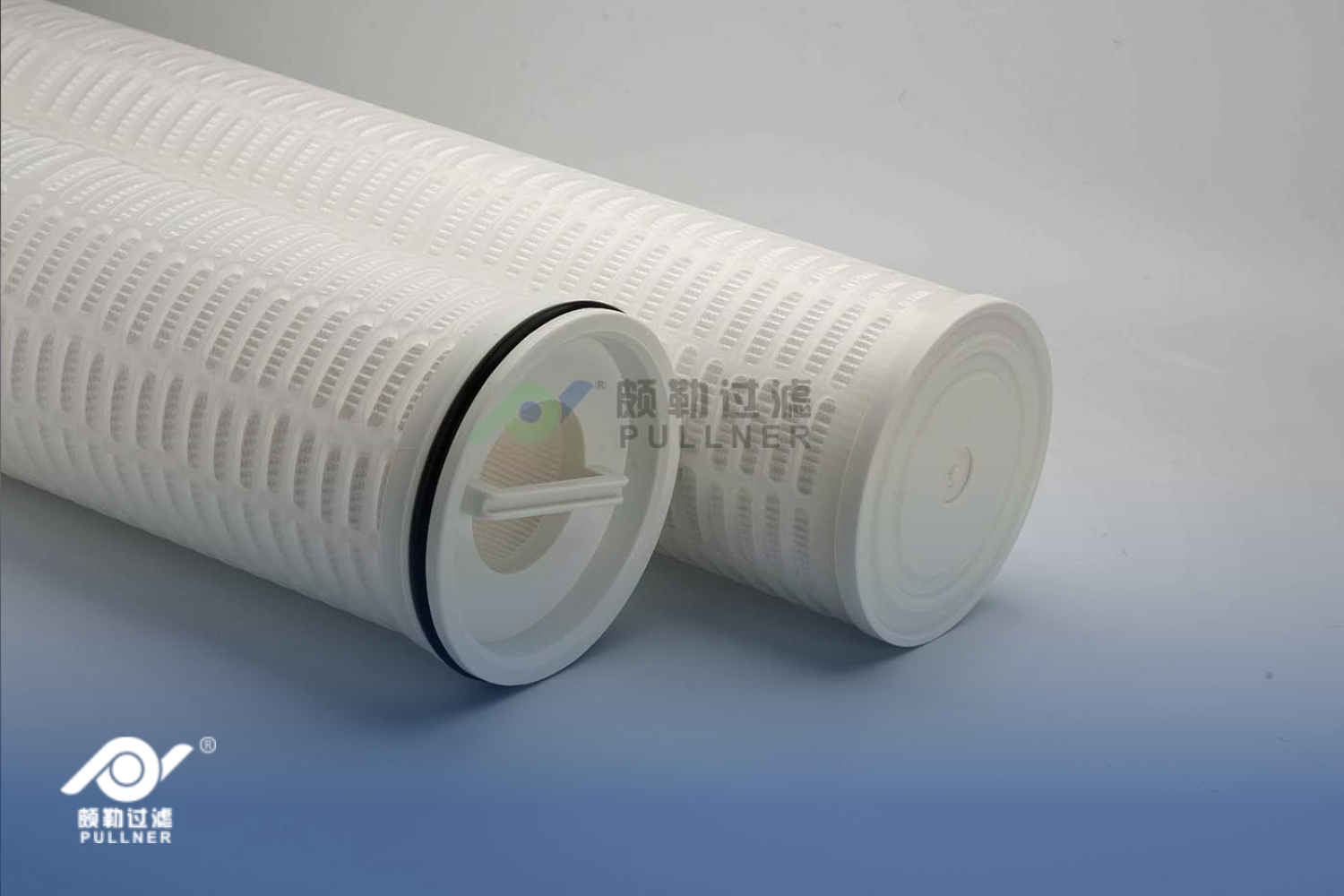

Primary filtration handles the bulk contaminant load using media, bag or cartridge filtration based on particle size and solids volume.

3. Fine Or Specialty Treatment

Fine stages add membrane systems like ultrafiltration, activated carbon, reverse osmosis or ultraviolet sterilization for purity, taste, odor control or microbial protection.

4. Distribution and Monitoring

Monitoring tracks flow and differential pressure so you know when backwash or element changeouts are needed. Automation options include valves, alarms and integrated control panels.

Industries We Serve with Commercial Water Filtration Systems

We build commercial water filtration systems for facilities that need predictable performance under real-world loads.

Food and Beverage Processing

You protect taste, hygiene and line performance by keeping ingredient, wash and rinse water consistent.

Hospitality and Resorts

You improve guest water quality while protecting plumbing, heating systems and back-of-house equipment.

Commercial Buildings and Campuses

You reduce scaling and fouling across central boilers, chillers and potable distribution.

Manufacturing and Assembly Plants

You stabilize process water for cleaning, machining, surface prep, coating and cooling loops.

Power Generation and Utilities

You lower corrosion risk and keep cooling and boiler feed systems efficient under continuous demand.

Healthcare and Laboratories

You deliver reliable water quality for sterilization, safety and sensitive equipment requirements.

Agriculture and Irrigation Operations

You reduce solids and organics that clog nozzles, drippers and pumps, improving system uptime.

Municipal and Private Water Suppliers

You add capacity or upgrade treatment to support dependable distribution and compliance.

Data Centers

You keep cooling loops clean and efficient, reducing scale, corrosion and particulate buildup that can compromise thermal performance and uptime.

Why Choose Pullner Filters for Your Commercial Water Filtration System?

Designed for Your Site

We size every system to your actual water report, flow demand and footprint so performance stays stable after installation.

Full In-House Manufacturing

Our machining, assembly and testing stay under one roof, giving you tighter quality control and faster lead times.

Wide Contaminant Coverage

From high-flow pretreatment to high-purity polishing, you get staged treatment that matches your target quality.

Cost-Effective Alternative to Imports

You get comparable performance without premium pricing or long shipping delays for replacement parts.

Reliable Consumables Supply

We stock cartridges, bags and media so scheduled maintenance doesn’t turn into downtime.

Engineering Support End to End

Our team supports selection, integration, commissioning and operator training for smooth rollout.

How to Choose the Right Commercial Water Filter System

Municipal, borehole, surface water and recycled water each bring different contaminant risks and seasonal shifts.

Use a water report or on-site analysis to rank what matters most, then size stages to remove those loads first.

Match filtration to the standard you must hit, whether that’s process specs, potable requirements or discharge limits.

Size for both average load and surge demand so pressure stays stable across your operating day.

Coarse stages handle the heavy solids burden, then fine stages polish to your spec. We select ranges based on particle profile and downstream sensitivity.

Backwash capability, element access and spares planning keep service predictable and affordable.

Look for verified testing, material traceability, real installation history and long-term parts support.

Commercial Water Filtration System FAQs

What’s the difference between a commercial and industrial water filter system?

Commercial water filtration usually supports buildings, hospitality sites or light production with moderate flow and standard water quality targets. Industrial filtration handles higher pressures, tougher contaminant loads and tighter process specs, often with more automation and redundancy.

Can I add reverse osmosis later?

Yes. If you start with strong pretreatment and primary filtration, you can add reverse osmosis later without redesigning the whole system. We plan your skid layout to make that upgrade straightforward.

What standards do your systems meet?

Pullner manufactures under ISO 9001 quality control. We configure systems to meet your potable, process or discharge standards based on your site requirements and local regulations.

How often do cartridges or bags need replacement?

Replacement schedules depend on your solids load, flow rate and operating hours. We set service intervals using your water report and differential pressure targets so changeouts stay predictable.

Get a Commercial Water Filtration Quote Today

Send your water report or site specs and we’ll recommend a staged commercial water filtration system that fits your flow, targets and budget.